What will a cultivated meat LCA look like in the future?

• Market Update • Feature

Creating real meat without the animal at commercial scale is now one step closer, with both UPSIDE Foods (a Synthesis portfolio company) and GOOD Meat achieving the greenlight to sell their “cell‑cultivated chicken” in the US in June 2023.

This is good news for the environment. In total, food production is responsible for a quarter of green-house gas emissions[i], of which almost 60% corresponds to the production of animal-based food.[ii] In addition, three quarters of habitable land is used for the production of livestock for meat and dairy. As a consumer, one of the quickest ways to reduce your carbon footprint is to change what you eat – for example by replacing meat and dairy with plant-based sources of protein.[iii]

However, the question remains, how does cultivated meat (the technology UPSIDE Foods is pioneering) – a completely new method of producing meat and is not plant-based – fit into this narrative? What is the environmental impact of cultivated meat today and, more importantly, what will it be in the future? How will cultivated meat compare in terms of environmental impact to the production of meat and other sources of protein?

What are LCAs and why are they important?

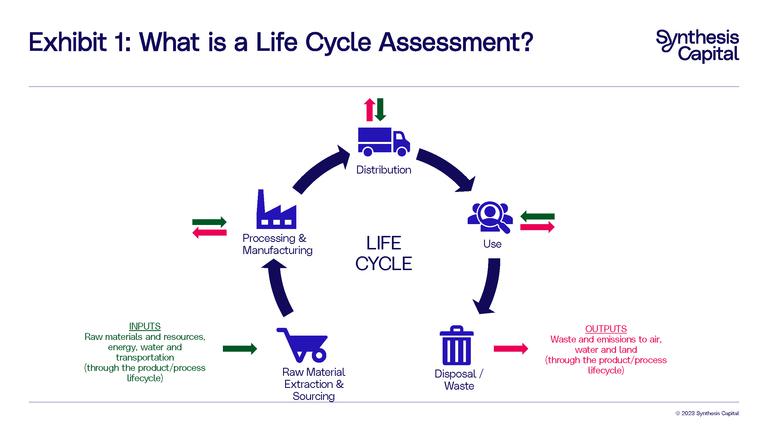

This is where Life Cycle Assessments (commonly referred to as LCAs) come in. LCA is the gold standard method for comprehensively evaluating the environmental impacts of a product, process, or service throughout its entire life cycle. It is an “input-output” analysis with the inputs being raw materials and resources, energy, water and land, and the outputs, atmospheric emissions, water pollution, and solid waste, all measured through all parts of the lifecycle. The five lifecycle stages are shown in Exhibit 1.[iv]

Today, LCAs have become a vital part of environmental management for companies and their methods and practices continue to evolve.

LCAs are a roadmap to improve environmental impacts

For any company in the alternative protein space, an LCA should be seen as a vital part of its ESG strategy. For this industry to truly succeed, and to be at the forefront of food production in the future, having a complete understanding of the overall environmental impact of production methods is key.

With this in mind, LCAs will play a key role, as they help alternative protein companies make informed decisions about their processes. However, LCAs do not have all the answers, and are not without their challenges (lack of data, subjectivity, assumptions and the ability to incorporate and understand systems change over time are a few examples of cited issues[v]).

These challenges are often magnified for LCAs of novel processes at pre-commercial scale, precisely because the process may rely on supply chains that themselves are not yet fully scaled, with little data, or because assumptions must be made about how a product may be used in the future, which can be inaccurate. As such, LCAs comparing novel to mature technologies can be misleading as they compare rapidly developing technologies with those with little room for improvement.

Don’t get us wrong, LCAs of novel processes are still extremely valuable. By asking important questions at the early stages of development, they help companies to understand the environmental consequences of different design options, to identify opportunities for process improvement, and importantly to guide decision-making early on, before full commercial scale is reached and it becomes harder to repurpose existing facilities.

LCAs provide a roadmap for product and process improvement. There is no perfect process after all! An LCA can identify "hotspots" or possible environmental pain points,[vi] allowing for targeted interventions. This is especially important for ground-breaking technologies like cultivated meat production, where we expect rapid scale-up in the coming years.

We need to accept that the results and conclusions of LCAs for cultivated meat will evolve in the future, with scale-up and commercialisation, and the better data that comes with it.

Earliest LCAs for battery electric vehicles pinpointed key impact areas

To understand this pathway in more detail, we wanted to take a brief look at how LCAs have changed when assessing another technology that has seen rapid progress – electric vehicles. The number of EVs is growing – and fast. In 2022, 14% of new car sales were EVs (up from 10% in 2022), and forecasts estimate up to 80% of new car sales will be EV by 2050.[vii]

We can trace early LCAs or environmental impact analysis for electric vehicles – or more precisely battery powered vehicles – to the mid 1990s. The early LCAs generally were not favourable for EVs, highlighting two key issues: the battery technology and the charging energy‑mix (both in terms of energy efficiency and fossil fuel reliance). A 1995 letter to Science stated that the only practical battery technology would be lead-acid;[viii] this was depopularised in the 2010s, and today most EVs use lithium-ion technology.

Since then, battery-technology has improved, the energy-mix being used to charge them has changed, and better and more up-to-date data for the whole EV supply chain has emerged. The number of LCAs published annually for electric vehicles consists of hundreds per year, and they are updated regularly to take into account more and more technology advances and better data. Now LCAs exist comparing different cars in different countries using a wide range of battery technologies.

Today, the scientific consensus is that electric vehicles outperform diesel and petrol cars in terms of greenhouse gas emissions across their lifecycle.[ix] Even so, the relative difference will continue to be updated, as we continue to see more breakthrough technological improvements in batteries. For example, just recently Toyota announced a potential technology breakthrough which could halve the cost, size and weight of their solid-state batteries allowing a range of 745 miles and a ten-minute charging time.[x]

LCAs for cultivated meat already exist, but will get more thorough

But why are EV LCAs relevant for cultivated meat? Well, EVs are a recent (i.e. within the history of LCAs) example of the rapid commercial scale-up of a novel technology. Over the time period where LCAs have been published for electric vehicles, we have seen huge technological advances and billions of dollars being put to commercial scale-up. Those initial LCAs published describe a totally different technology and backdrop to the one we have today. But they were still extremely valuable – pinpointing battery technology and energy-mix as the crucial environmental impact drivers.

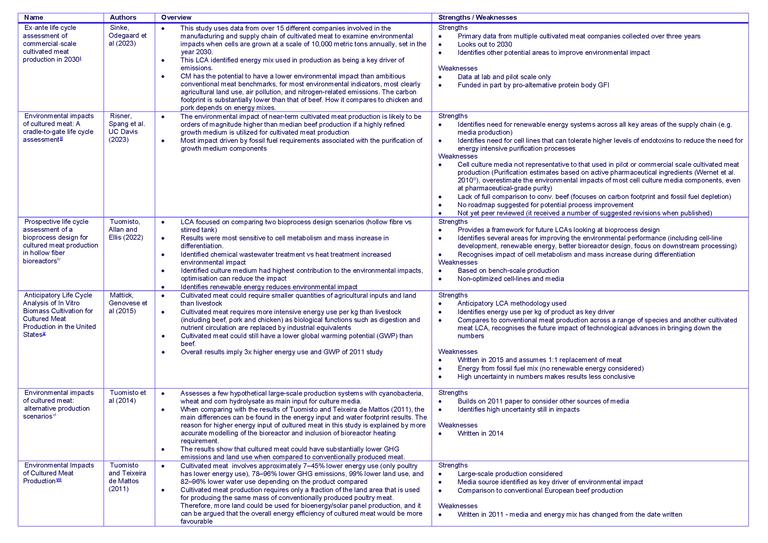

Cultivated meat LCAs should be viewed in line with early EV LCAs – a guideline for where the processes need to improve. Fortunately, there are already a number of cultivated meat LCAs in the public domain, with a variety of conclusions (ranging from positive to an assertion the technology will never be competitive) but all highlighting key areas of focus (see Table below for an overview of some of the main academic papers published to date).

Specifically, just as the early LCAs for EVs identified battery technology and charging infrastructure as key drivers of environmental impacts, these early cultivated meat LCAs have identified the source of energy (both directly and indirectly used), and media composition and production as key focus areas. One area of agreement for all LCAs to date is that land use for cultivated meat will be significantly reduced compared to livestock. As some papers point out, how that land is used, for example to grow biofuel, for solar panels or for the provision of ecosystem services (forests or natural conservation areas) could actually increase the environmental benefit of cultivated meat further across a range of metrics.

How will cultivated meat LCAs improve?

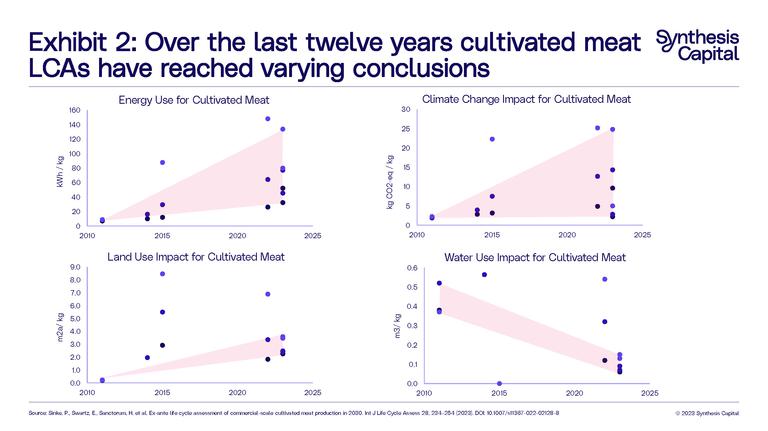

Published cultivated meat LCAs are not necessarily showing an improving outlook for the environmental impact. Our summary in Exhibit 2 shows how conclusions for these key LCAs for four metrics (energy use, climate change (global warming potential or GWP), land use, and water use) has changed. Interestingly, for energy use and climate change it is the range of estimates that has expanded (i.e. uncertainty has increased). Perhaps this is unsurprising given the increasing number of scenarios used in the LCAs. Interestingly, the best case for the most recent LCA has not significantly increased since Tuomisto’s 2011 study. Meanwhile, estimates for expected land use have grown, but still remain much better than the conventional meat alternatives, and estimates of expected water use have actually fallen since 2011.

A critical factor to take into account is that cultivated meat production is not yet at commercial scale. Scale will bring more efficient processes and rapid cost declines. The underlying technologies and processes, such as the cost and composition of media, are continuing to see further innovation bringing down the cost and environmental impact. For example, glucose, a major cost component of fermentation based technologies (such as precision fermentation which is often used to produce growth factors for cultivated meat production) and also an input into cultivated meat production itself is finding other alternative routes as we discuss in our Insights piece: “Can we scale glucose production?”

These are just a couple of the key opportunities for technological improvement and product differentiation that have the scope to improve environmental impact. Other opportunities are as follows:

First, cultivated meat is not a one-for-one replacement

Most existing cultivated meat LCAs compare a kg of cultivated meat to a kg of animal produced meat. However, in the short-term the majority of cultivated meat will not be consumed in 100% cultivated meat products. Predominantly, it will be used as an ingredient, in some cases as low as 5% of the final product, which vastly changes both the cost and impact metrics. The benefits of these hybrid products, where cultivated meat is mixed with plants and fat to provide a better taste and nutrition performance, will be a key go to market strategy for many companies. This will be extremely environmentally impactful, especially when you start comparing a kilogram of cultivated meat to a kilogram of cow. The average “dressing” percentage (the weight of the carcass available vs the weight of the animal) is around 60%. This percentage can be lower when considering different breeds, age or gender.[xviii] This loss and variability is not an issue the cultivated meat will have to such a scale as the conventional meat industry, and something we do not believe is fully factored into current environmental impact analyses.

It is worth noting that we do expect 100% cultivated meat products to become available in the longer term; as cultivated meat becomes more economically efficient, these efficiencies will likely also translate to the environmental side.

Second, how is cultivated meat going to be different?

Currently most of the LCAs for cultivated meat have focused on the supply-chain up to and including production. For the most part, post-production, the assumptions are that cultivated meat will have a similar lifecycle. However, these assumptions are likely flawed. For example, food waste may look very different, as we know cultivated meat has less risk of contamination leading to products with longer shelf lives (compared to conventionally produced meat where food-borne diseases can be introduced through processing – particularly at slaughter). Cultivated meat may also need less refrigeration because of this lower risk of bacterial contamination. In addition, cultivated meat can be produced anywhere, so the environmental impact from transport will likely vary i.e. “food-miles” will decrease. While we are too early in this food transition to understand the full impacts of this today, this will likely be a key factor of future LCAs.

Third, can land use change enhance environmental benefits?

It is likely as cultivated meat production scales up we will see more LCAs focusing on directly comparing cultivated meat production with its animal equivalent. As part of this we may see cultivated meat companies addressing the potential benefits far more directly. For example, on land use it is well understood that cultivated meat (and indeed all alternative protein production) uses significantly less land, both for keeping animals and growing feedstocks. However, how this land is used could actually count as an environmental benefit in LCAs. We may see cultivated meat companies and others directly pursuing using this land in ways to offset emissions as part of a bigger strategy. For example, by rewilding, or using the land for renewable energy production. A recent study aimed to quantify how reforesting land currently used for animal agriculture can actually offset emissions.[xix]

Fourth, LCAs are only good as the data being used

Technology is changing so quickly in the cultivated meat sector that LCAs simply cannot reflect the most recent data. As production scales up, we will see higher quality data more reflective of actual practices in the space.

For example, a common practice is to use data from the biopharmaceutical industry, which grows animal cells to produce cellular or protein therapeutics, in cultivated meat LCAs. However, these data are not comparable on cost nor scale. The food industry will need to maximise processes for high volumes and low costs – not something the pharmaceutical industry has needed to do as much. As cultivated meat production scales in the next few years, LCAs will be able to use data reflective of the actual processes.

Conclusion

Just as the first LCAs for electric vehicles pinpointed battery technology and energy-mix for charging as key areas of environmental impact, early LCAs have shown that media production and energy mix for bioreactors will be the key drivers for cultivated meat production.

What the early electric vehicle LCAs didn’t take into account was the vast technological improvement coming for batteries and indeed behind energy mixes globally, as we have seen investment and growth in solar photovoltaics and wind turbines starting to move us to a more renewable future (something that will also have huge implications for cultivated meat).

We need to view LCAs for cultivated meat in the same way, a future path but not a manifesto. Nevertheless, LCAs remain important for developing cultivated meat technology – crucial in transitioning us away from animals in our food system – in the most environmentally efficient way possible. The industry’s understanding of how production processes are lacking today and how they can be improved in future will continue to evolve as the industry grows.

For us at Synthesis we wholeheartedly believe in the future environmental benefit of cultivated meat and all the alternative protein technologies, and look forward to future LCAs building on better data as the industry evolves and scales.

[i]

This data is from Our World in Data’s summary of the Environmental Impacts of Food which itself sources the data from Poore, J., & Nemecek, T. (2018). Reducing food’s environmental impacts through producers and consumers. Science, 360(6392), 987-992.

[ii] Xu, X., Sharma, P., Shu, S. et al. Global greenhouse gas emissions from animal-based foods are twice those of plant-based foods. Nat Food 2, 724–732 (2021). https://doi.org/10.1038/s43016...

[iii] Less meat is nearly always better than sustainable meat, to reduce your carbon footprint. Our World in Data. H. Ritchie. February 2020.

[iv] To increase reliability and transparency, a systemized framework for conducting LCAs was released by the International Organization for Standardization (ISO) in the late 1990s, which was updated in 2006. Today these standards are amalgamated into ISO 14040 and 14044 and are the leading international standards. The LCA standards set out by ISO focus mainly on the process of performing an LCA, following a product’s impact from cradle to grave. ISO 14040 describes the ”principles and framework for LCA”, while the ISO 14044 “specifies requirements and provides guidelines” for LCA. Other countries have also formulated a variety of standards and guidelines for LCAs. For example, the EU’s International Reference Life Cycle Data System (ILCD) which is consistent with the ISO standards and France’s BPX 30-323 series, which describes the method for assessing the life cycle environmental impact of various products.

[v] Some of the continuing issues with LCAs are: 1. Lack of data: Getting accurate and comprehensive data for the entire life cycle of a product or process is challenging. This can make it difficult to conduct a thorough assessment. 2. Deciding what to include: It's subjective to determine what processes or impacts to include or exclude in an LCA. Different choices can lead to inconsistent results and make comparisons tricky. 3. Allocating impacts: Dividing environmental burdens among different products or stages is complicated. This can affect the results and interpretations of the assessment. 4. Systems change over time: LCA assumptions and models may not keep up with changes in technology, energy sources, or supply chains. This can make it challenging to accurately assess emerging technologies or evolving systems. 5. Understanding and using the results: Interpreting and communicating LCA findings can be difficult, especially for decision-makers. LCA results don't provide clear-cut decisions but rather inform decision-making alongside other factors. 6. Limited focus on sustainability: LCA primarily looks at environmental impacts and may not consider social, economic, and ethical aspects fully. This means it may not provide a complete picture of a product or process's overall sustainability.

[vi] Hauschild, Michael Z.; Rosenbaum, Ralph K.; Olsen, Stig Irving (2018). Life Cycle Assessment || LCA History. , 10.1007/978-3-319-56475-3(Chapter 3), 17–30. doi:10.1007/978-3-319-56475-3_3

[vii] As of June 8, 2023, BNEF forecast 100 million passenger EVs on the road by 2026 and 700 million by 2040. Press releases can be accessed here.

[viii] Lester B. Lave et al. , Environmental Implications of Electric Cars. Science 268, 993 -995(1995). Article can be accessed here.

[ix] There are many sources for this. I found this article from MIT a good summary of the current scientific consensus.

[x] Toyota’s claims were first reported in the Financial Times. Article accessed here.

[xi] Sinke, P., Swartz, E., Sanctorum, H. et al. Ex-ante life cycle assessment of commercial-scale cultivated meat production in 2030. Int J Life Cycle Assess 28, 234–254 (2023). DOI: 10.1007/s11367-022-02128-8

[xii] Environmental impacts of cultured meat: A cradle-to-gate life cycle assessment, Derrick Risner, Yoonbin Kim, Cuong Nguyen, Justin B. Siegel, Edward S. Spang DOI: https://doi.org/10.1101/2023.0...

[xiii] Wernet, G., Conradt, S., Isenring, H. P., Jiménez-González, C., & Hungerbühler, K. (2010). Life cycle assessment of fine chemical production: a case study of pharmaceutical synthesis. The International Journal of Life Cycle Assessment 2010 15:3, 15(3), 294–303. https://doi.org/10.1007/S11367...

[xiv] Hanna L. Tuomisto, Scott J. Allan, Marianne J. Ellis, Prospective life cycle assessment of a bioprocess design for cultured meat production in hollow fiber bioreactors, Science of The Total Environment, Volume 851, Part 1, 2022.

[xv] Mattick, Carolyn S.; Landis, Amy E.; Allenby, Braden R.; Genovese, Nicholas J. (2015). Anticipatory Life Cycle Analysis of In Vitro Biomass Cultivation for Cultured Meat Production in the United States. Environmental Science & Technology, 2015, 49, 19, 11941–11949. DOI:10.1021/acs.est.5b01614

[xvi] Tuomisto HL, Ellis MJ, Haastrup P (2014) Environmental impacts of cultured meat: alternative production scenarios. In: Schenck R, Huizenga D (eds) Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-food Sector. ACLCA

[xvii] Tuomisto, Hanna L.; Teixeira de Mattos, M. Joost (2011). Environmental Impacts of Cultured Meat Production. Environmental Science & Technology, 45(14), 6117–6123. DOI:10.1021/es200130u

[xviii] Penn State Extension. Data on the dressing percent of a variety of types of cattle is shown here.

[xix] https://journals.plos.org/climate/article?id=10.1371/journal.pclm.0000010