Precision Fermentation: Pathways to Cost Parity

• Technology • Opinion

Precision fermentation has huge potential, but costs must come down

Precision fermentation has the potential to be one of the most transformative technologies of our lifetime. Through precision fermentation, we can use cells as factories, engineering yeast, bacteria, and other microorganisms to produce foreign molecules, including specific enzymes, proteins or fats. At Synthesis, we are particularly interested in the use of precision fermentation to produce dairy, egg, and other animal proteins or fats, which can be used to create the food products we love without using animals and with a fraction of the environmental impact. This technology is not new; precision fermentation is already widely used to produce certain enzymes and high-value ingredients, including chymosin an enzyme used in cheesemaking. But today the application of the technology is broadening well beyond these categories.

However, there is one major barrier to precision fermentation becoming a mainstream production method for commodity animal ingredients, and that is cost. Today, it is much more expensive to produce a kilogram of bovine whey protein via precision fermentation than it is via a cow. If we want this technology to become a mainstream production method, costs must fall. Precision fermentation will not reach widescale adoption until producers innovate to achieve parity with animal proteins, specifically on taste and price [i].

One means of reducing costs comes simply through scaling up, but scaling the existing tech alone will not bring precision fermented animal fats and proteins to cost parity. In addition, we need innovation across the full technology stack to improve efficiency at all steps in the process. Fortunately, there is a playbook of cost improvement technologies under ongoing development. These can be applied to both novel strains, such as baking/brewing yeast S. cerevisiae, and novel strains, such as engineered T. reesei. It is these enabling technologies that will propel the precision fermentation industry forward, seven of which we dive into below.

More Productive Host Organisms

Engineering enhanced microbial strains to yield higher concentrations of the desired end product in shorter quantities of time can lead to significant cost improvements. When referring to the host organism’s productivity, we look at titres and fermentation time. Titres measure the amount of the end product relative to the volume of liquid in which it was produced (titres are typically referred to in grams per litre). There are many companies working on boosting host organism productivity through a range of technologies known broadly as strain engineering. Triplebar, a Synthesis portfolio company, has built a Hyper-Throughput™ screening platform which acts as a microprocessor for biology, integrating hardware, software, biology and biochemistry to miniaturize and accelerate evolution to improve the performance of strains and cell lines [ii]

Better Feedstocks

Bacteria and fungi used in precision fermentation need to be fed sugar, which is commonly referred to as feedstock. Currently, most precision fermentation players feed their host organisms glucose from crops like corn and wheat. Feedstock costs can easily make up over half of the total cost per kilogram of end product. With the bioeconomy’s glucose demand projected to surpass supply in the coming decades, it’s crucial that precision fermentation players find ways to utilize cheaper, non-food carbon waste streams [iii]. Hyfe, a Synthesis portfolio company, is transforming food processing waste into feedstocks for biomanufacturing. Hyfe’s approach will not only cut costs, but also further decrease the environmental footprint of production by leveraging existing waste streams.

Better (& Bigger) Bioreactors

Scaling up to larger bioreactors will improve costs as long as titre, rate, and yield can be maintained. Still, more innovation is needed beyond just larger versions of the same tanks. Today, most precision fermentation is done using stirred tank bioreactors, which use agitators to mix and aerate the culture. Upgrading bioreactor design and operation protocols can further enhance performance. These advanced designs may improve mixing and aeration, which can lead to more efficient growth. New bioreactor technologies should be used and optimized along the scale-up journey. This will minimize the technical risks, time, and cost when moving from lab to pilot to commercial production.

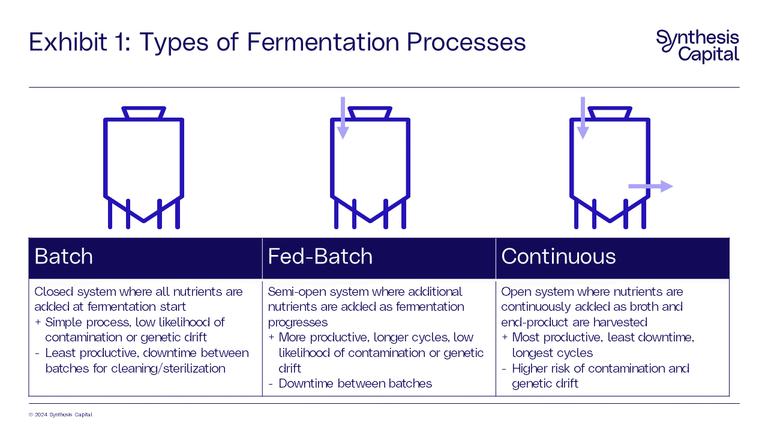

Continuous Fermentation

Currently, the precision fermentation industry relies predominantly on fed batch processing. In this approach, the fermentations are completed in discrete batches and are stopped once productivity plateaus. After harvest, the bioreactor is cleaned and sterilized before a new batch can be started again. While this process minimizes risk of genetic drift or cross contamination, it is inefficient and costly, largely due to the downtime between batches. Given this, some companies are working on continuous fermentation technologies, in which new feedstock is added as the broth is harvested, allowing for much longer runs and higher output. Given the high costs of bioreactors and other fermentation equipment, continuous fermentation would allow companies to make significantly better use of their equipment, reducing both capital expenditure and operating expenditure.

Improved Downstream Processing

The extraction of the target end product from the fermentation broth can account for up to 85% of the costs when manufacturing biologics [iv]. While food ingredients may not require the same purity levels as biologics, optimizing the purification steps will still increase product recovery and decrease costs. Downstream processing may be able to be improved via advances in filtration techniques, chromatography, real-time monitoring, and automation.

Biomass Valorisation

After downstream processing and extraction of the end product, a significant amount of spent fermentation broth and host organism biomass is left behind, which - depending on makeup and regulatory requirements - could be repurposed or sold. Precision fermentation companies are beginning to explore side-stream valorisation when designing commercial scale processes for both cost and environmental impact reduction. As the bioeconomy grows, it will be essential for companies to implement circular manufacturing processes [v].

Artificial Intelligence & Machine Learning

Artificial intelligence and machine learning have the potential to significantly accelerate the development of many enabling cost improvement technologies, including better microbial strains, alternative feedstocks, and more efficient bioprocesses. These advanced algorithms rely on the availability of large volumes of high-quality data. In addition to making use of existing data, investing in technologies that facilitate rapid and low-cost data collection will be crucial to harnessing the potential of AI in this field.

In Closing

Precision fermentation has the potential to transform our food system, but only will live up to this potential once its products are price competitive and delicious. By leveraging advancements in strain engineering, feedstocks, equipment, and processing, the industry can overcome cost barriers. If provided with plentiful, high-quality data, AI is poised to be a helpful tool in accelerating the development of these enabling technologies. To reach widescale adoption, all of these innovations need to work, and they need to work together. Companies should be pursuing these cost improvement measures in tandem and at all stages of their scale up, from bench to pilot to commercial production.

Just as a suite of improvements were necessary for electric vehicles (EVs) to achieve market penetration, the same will be true for precision fermentation [vi]. In EVs, battery costs plummeted, ranges increased, and cars became more desirable [vii]. Further, electric vehicle makers continue to improve on pain points such as charging networks, vehicle weight, and the environmental impact of battery components. Similarly, we are poised to see continued improvements in precision fermentation as companies find breakthroughs across key levers. This progress will be crucial in establishing precision fermentation as a sustainable and cost-effective production method, which is important in all applications, but especially so in low-cost, commodity animal proteins and fats. Ultimately, we must keep sight on end goal, which is to produce affordable, delicious food with a fraction of the environmental impact.

References

[i] Synthesis Capital, Boston Consulting Group, and The Good Food Institute (2024) - “What the Alternative Protein Industry Can Learn from EV Companies”

[ii] Synthesis Capital (2023) - “The Future of Food Starts With Better Cells: Why We Invested in Triplebar”

[iii] Synthesis Capital (2023) - “Feeding Our Future Food System: Can We Scale Glucose Production”.

[iv] Blake Byrne (2023) - “Precision fermentation’s capacity craze: Have we lost the plot?” Published online at TechCrunch.com

[v] Synthesis Capital (2023) - “From Linear to Circular: How Alternative Proteins and a Circular Food System Can Help Feed the Planet”

[vi] Synthesis Capital, Boston Consulting Group, and The Good Food Institute (2024) - “What the Alternative Protein Industry Can Learn from EV Companies”

[vii] Synthesis Capital, Boston Consulting Group, and The Good Food Institute (2024) - “What the Alternative Protein Industry Can Learn from EV Companies”