Unlocking the Future of Biomanufacturing with Continuous Fermentation: Why We Invested in Pow.Bio

• Investment • Opinion

Fermentation is one of humanity’s oldest biotechnologies.[i] For millennia, civilisations have used microbes to transform raw ingredients into food and drink. Beer, bread, yogurt and soy sauce are just a few examples of the output from this ancient craft.

For most of history, fermentation was a spontaneous process. But by the mid-19th century, scientists like Louis Pasteur began to harness the mechanics behind it, laying the groundwork for industrial-scale applications.[ii] This knowledge led to the development of fed-batch fermentation, a process in which microbes are grown in a sealed vessel, produce a desired product, and are then harvested in cycles. But while effective, fed-batch fermentation is inherently inefficient.

The Bottleneck in Biomanfuacturing

Biomanufacturing holds immense promise for a more sustainable future, enabling the production of bioproducts including alternative proteins, biomaterials, biochemicals and biofuels, which can have significantly better environmental footprints than conventional fossil or animal-derived products. However, despite its huge potential, the biomanufacturing industry faces a critical challenge: cost. While cost is less of a concern for high-value products like pharmaceuticals, it’s a major barrier for lower-margin, commodity bioproducts.

Unlocking the widespread adoption of alternative proteins and other bioproducts will require large unit cost improvements that enable products to be brought to market at competitive prices. And yet, some of the processes we rely on for fermentation-derived alternative protein production are outdated. For decades, we’ve made incremental improvements. Better strains. Cheaper feedstocks. More efficient downstream processes. But one fundamental bottleneck remains: fed-batch fermentation. Each cycle in fed-batch fermentation requires stopping the entire system to harvest, clean, and sterilise the bioreactor before starting again, creating substantial downtime and wasting productive biomass.

It’s the heart of the system. Stop-start, inefficient, and therefore unsuited for the high-throughput production and cost reductions we now demand. Businesses that want to profitably produce and scale fermented products are in need of a better system - a continuous system - that boosts productivity without relying on larger, more expensive bioreactors.

Luckily, continuous fermentation isn’t a new idea. It’s already been demonstrated at commercial scale for a variety of bioproducts, like Quorn’s fusarium-based protein. But despite its promise, widespread adoption has been limited by persistent challenges, explored below.

Pow.Bio: A Breakthrough in Continuous Fermentation

Pow.Bio’s (’Pow’s) vision is to be the ‘unlock’ for biomanufacturing. The company achieves this through its continuous fermentation platform. This platform is ‘continuous’ because it allows fresh feedstock to be added as product is simultaneously harvested, creating a steady-state process. Unlike fed-batch fermentation, Pow’s continuous system significantly increases productivity, reducing production costs and accelerating time to market.

The challenge has always been making continuous fermentation accessible, reliable and scalable. Pow.Bio is solving this challenge.

In the context of alternative proteins, the productivity gains from Pow’s continuous platform could revolutionise the ability of single-cell and precision fermentation-derived products to reach cost parity with animal-based products and capture market share. Furthermore, it could allow alternative protein and ingredient companies to iterate more quickly on end-product formulations with potential customers. As a result, Pow’s platform could be a critical enabling technology to drive the commercialisation and adoption of alternative proteins and other biobased products.

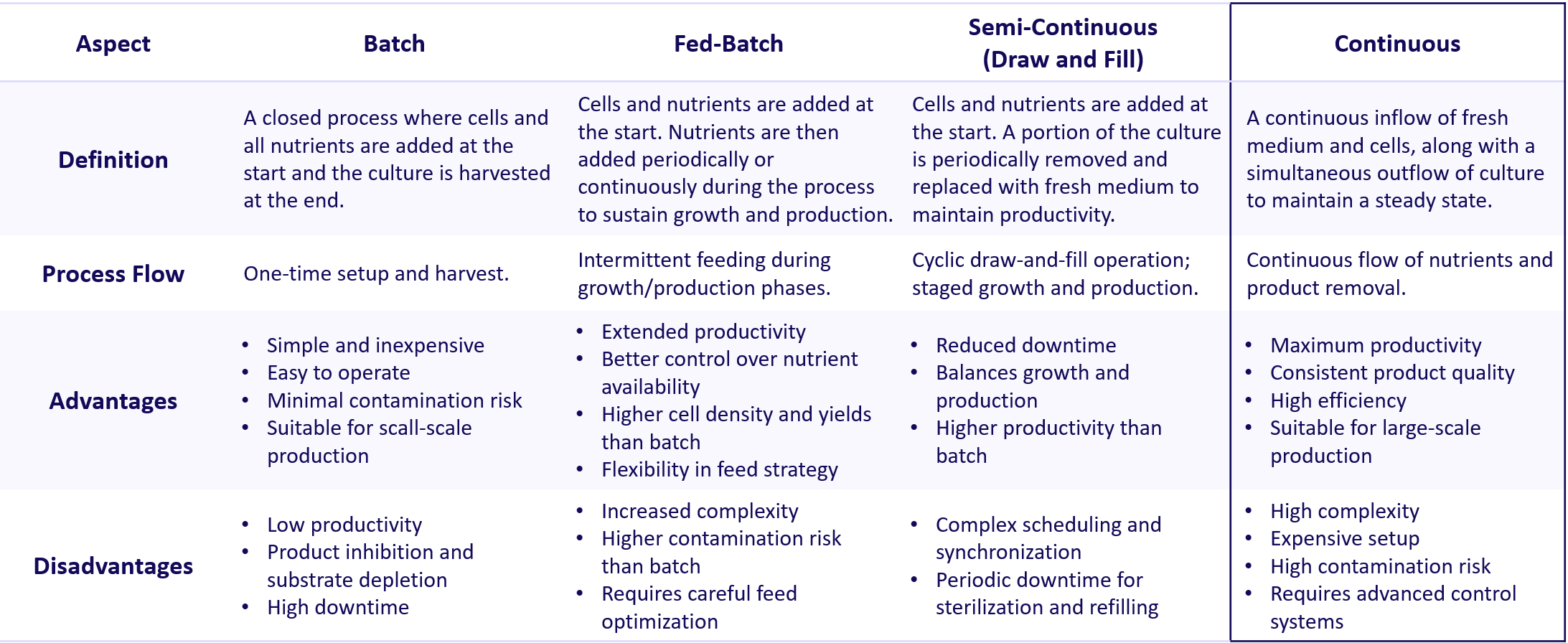

Figure 1: Comparison of fermentation processes

Although continuous fermentation has been explored for decades and offers clear advantages over fed-batch processes, it has yet to become an industry standard. This is largely because no company has been able to overcome the key technical barriers to operating continuous fermentation processes over long periods of time: bioreactor contamination, genetic stability and process control. By contrast, Pow has been able to overcome these in the following ways:

- Bioreactor contamination: Maintaining sterility over extended periods is more difficult in continuous systems. Pow has developed a proprietary fermentation media formulation and optimised two-bioreactor system that tightly controls fermentation conditions, reducing the risk of contamination by unwanted organisms.

- Genetic stability: Continuous fermentation runs for extended periods of time, increasing the risk of genetic mutations in host strains and cells. Again, Pow’s unique bioprocess design and media formulation mitigates this issue, allowing for long-term, stable production without loss of yield.

- AI-powered process control: Pow’s AI-enabled system continuously monitors and adjusts process conditions in real time, optimising performance and ensuring consistent, reproducible results at scale.

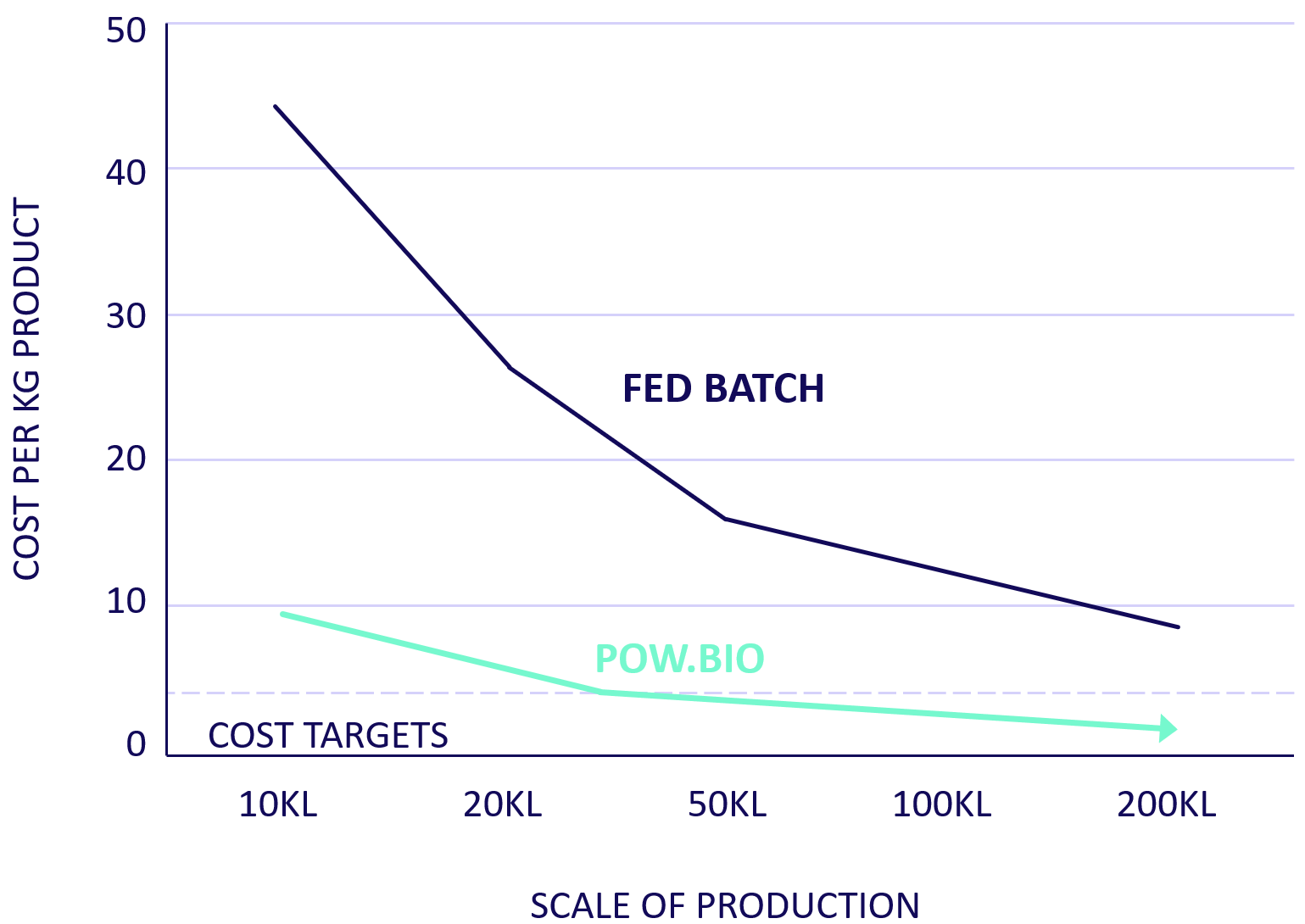

The result? Pow’s platform delivers two to five times the product output per unit of feedstock at any scale, resulting in unit cost reductions of 50-80% compared to fed-batch fermentation, as well as significantly lower capex costs (see below).[iii]

Figure 2: Pow.Bio’s unit costs are significantly lower at any scale

The Pow.Bio Advantage

Like Pow, other companies have developed continuous fermentation technologies. However, many of these are limited in scope, have not demonstrated consistent results at scale, or have not addressed all three challenges of contamination, genetic stability and process control, described above. Pow’s platform stands out amongst both fed-batch and continuous competitors by scoring highly on four important areas:

-

Capital-efficient approach to scaling biomanufacturing:

Scaling biomanufacturing is typically capital-intensive, requiring new custom infrastructure that takes years to build. Pow’s platform is differentiated as it is bioreactor agnostic, allowing customers to utilise existing equipment. The technology can be transferred and deployed by cheaply converting and retrofitting existing fed-batch manufacturing facilities that are owned and operated by CDMOs and end product companies. As a result, Pow estimates that its conversion costs are just 1% of the cost of constructing a greenfield biomanufacturing site, and site conversions can be completed in months rather than years. This capital-light model positions the company to drive rapid adoption across the biomanufacturing industry, and will be monetised by licensing / royalty agreements.

-

AI-driven software turning data into actionable insights:

Pow.Bio’s AI-driven software is transforming continuous fermentation by turning vast amounts of data into actionable insights that will deliver enhanced manufacturing performance and process optimisation for customers. Indeed, Pow has demonstrated that its software can rapidly iterate using data from initial runs to identify optimal conditions for many parameters in parallel, and continuously improve productivity in real time. When combined with its hardware and bioprocess innovations, this sets Pow apart from its competitors.

-

Broad applicability across industries, including and expanding beyond food:

Whilst other companies have developed continuous fermentation technologies, many of these are not ‘broadly applicable’ platforms, but are instead designed for specific use cases. Pow’s technology has already been successfully validated across a huge range of molecules, microbial hosts, industrial applications and customer profiles. Indeed, Pow has not yet observed any limitations on the types of products that it could make. This means the company’s addressable market is large and diversified, constituting a significant component of the $800bn biomanufacturing industry.[iv, v] Within alternative proteins, Pow is helping companies scale the production of precision fermentation-derived proteins at unit costs that make commercial adoption viable.

-

Sustainable platform driving reductions in greenhouse gas emissions:

Pow’s more efficient platform significantly reduces CO₂ emissions and utility consumption compared to fed-batch fermentation processes. Additionally, in acting as an enabler for the broader biomanufacturing industry, and making scalable and cost-effective bioproduction a reality, Pow has the potential to drive systemic reductions in greenhouse gas emissions.

Our Vision of a Sustainable Food System

At Synthesis Capital, enabling technologies like continuous fermentation have always been a foundational part of our investment strategy.

Our vision of a sustainable food system does not consist of technologies or products in silos, but of multiple solutions working together to create the future of food. This is a highly interconnected ecosystem where innovative technologies like Pow’s drive meaningful, system-level change, alongside other enabling technologies. It’s only by stacking these innovations across the entire biomanufacturing process that we can reach cost parity with conventional commodity protein production.

We are thrilled to have invested in the company’s pre-Series B bridge round, and to be partnering with the highly talented Pow.bio team. Pow’s continuous fermentation platform represents an important step forward in overcoming the cost barriers that have held back precision fermentation for so long. We believe that addressing these cost barriers is central to the widespread adoption of alternative proteins, and are excited about Pow’s potential to unlock a new era of cost-effective biomanufacturing, and to help build strong foundations for our future food system.

Sources

[i] Taveira, I.C., Nogueira, K.M., Oliveira, D.D., & Silva, R.N (2021) - Fermentation: Humanity’s Oldest Biotechnological Tool. Available at: https://api.semanticscholar.org/CorpusID:239021394

[ii] Britannica (2025) - Louis Pasteur. Available at: https://www.britannica.com/biography/Louis-Pasteur

[iii] This projected impact is based on the platform’s success across multiple product classes. Examples include biomass, enzymes, organic acid, and protein.

[iv] McKinsey Global Institute (2020) - The Bio Revolution: Innovations transforming economies, societies, and our lives. Available at: https://www.mckinsey.com/industries/life-sciences/our-insights/the-bio-revolution-innovations-transforming-economies-societies-and-our-lives

[v] World Economic Forum (2024) - Why the Global Bioeconomy Urgently Needs Technical Standards and Metrics. Available at: https://www.weforum.org/stories/2024/06/international-effort-addresses-the-urgent-need-for-technical-standards-and-metrics-for-the-global-bioeconomy/