How Chemistry is Being Used to Produce Superior Alternative Fats: Our Investment in Savor Foods

• Investment • Opinion

Taste is paramount for any food product. Companies developing alternative products must optimise for taste; without this, there will never be a meaningful shift away from conventional animal-based food. Fat is a crucial ingredient in the taste profile of animal-based meat and dairy products, contributing to the juiciness and tenderness of a steak and the creamy mouthfeel of milk and ice cream. Indeed, many of the sensory characteristics that elevate the experience of consuming conventional meat and dairy versus the alternatives on the market today, arise from the profile and composition of fatty acids.

The use of biological systems – plants, microbes, animal cells – to produce ingredients that mimic the functional properties of those found in meat and dairy products is at the centre of the transition to a better food system and our focus at Synthesis. But what if biology isn’t the best or the most efficient tool to make all of the ingredients required for great tasting, competitively priced products? Our exploration of the alternative fat ecosystem revealed an alternative technology.

Background to fat and its importance

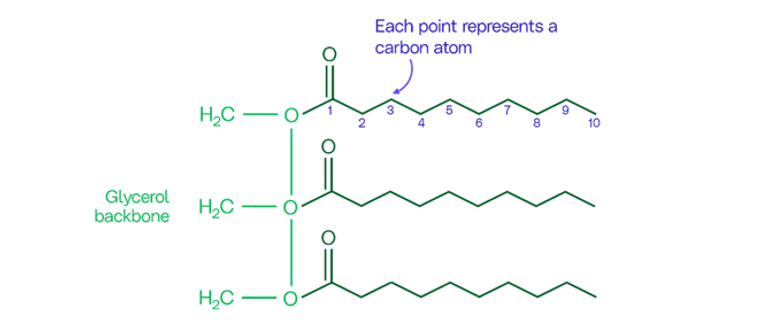

Dietary fat, one of the three key macronutrients, typically comes from one of two sources: animal fats, and vegetable fats and oils. These fats and oils have a specific chemical composition that produces several unique and important nutritional, functional and sensory properties. Specifically, fat molecules, known as triglycerides, have a chemical structure consisting of three fatty acid chains attached to a glycerol backbone, as shown in Figure 1 below. This chemical structure, which is much simpler than the structure of many proteins found in meat and dairy products, is the foundation of various types of dietary fats.

Figure 1: A fat molecule

Fat plays an important role in a healthy, balanced diet. It serves as both an energy store and source, boasting the highest caloric density versus carbohydrates or proteins. From a nutritional perspective, fats are essential for human health due to their provision of essential fatty acids (EFAs), which play primary roles in energy production, cell structure, gene regulation, body homeostasis, and disease prevention[1],[2]. Fats and oils are also essential vehicles for the absorption of fat-soluble vitamins, such as vitamin A and vitamin E.[3]

As mentioned earlier, fat also plays a critical role in the sensory attributes of meat and dairy products. The interaction between protein and fat creates the optimal texture and flavour profile in a creamy butter, a rich ice cream, or an aged cheese. More specifically, the fatty acid profile in animal fat, and the production of volatile compounds from those fatty acids during processing and cooking, creates the unique flavours and aromas we associate with each type of meat and dairy product[4],[5].

Commodity oils lack these critical properties

To date, the alternative protein industry has mainly relied on commodity oils from canola (rapeseed), sunflower, coconut, and palm to provide these functional and sensory properties at costs that do not negatively impact the overall cost of the end product. The smoke point, melting point, and other attributes of these commodity oils do not match those of animal fats and – as a result – hinder product developers from creating meat and dairy analogues that look, smell, and taste like their animal-based counterparts. In addition, coconut and palm oil have sustainability challenges, which will worsen as demand for these ingredients increases. As a result, there are significant opportunities for novel alternative fats, but to succeed, they must have superior flavour, texture, and other sensory attributes whilst being cost competitive with conventional plant-based oils.

Exploring biological solutions to produce alternative fats

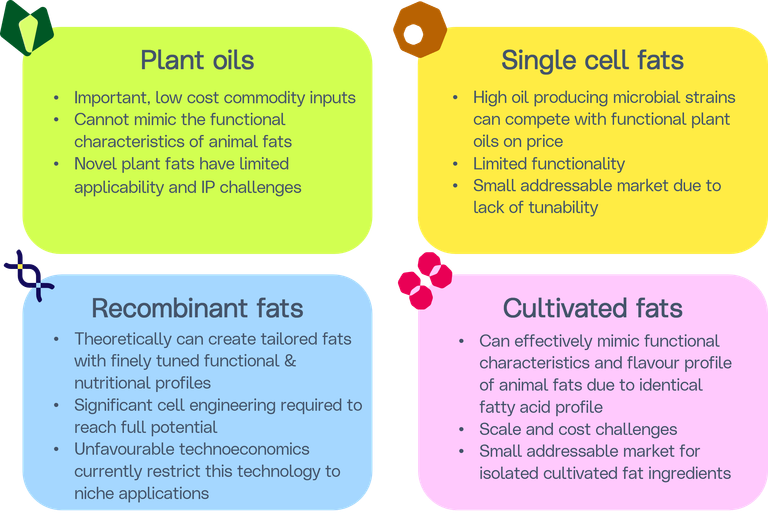

Our work on alternative fats began with an extensive technology deep-dive to explore biological solutions to produce better alternative fats across each of our four technology verticals (plant-based, single cell, recombinant, and cultivated). We used the analysis and findings of this deep-dive to map the most interesting alternative fat companies in each of our verticals.

Biological systems are well suited for protein production, as exemplified by some of our existing portfolio companies, such as Mozza, which is harnessing plants to produce complex dairy proteins. However, our work on fats revealed inherent limitations for producing alternative fats using biology. Indeed, we could not find a company that met all of our key investment criteria within our 5-10 year investment horizon.

Our assessment of each technology vertical for producing alternative fat is summarised in Figure 2 below.

Figure 2: Biological systems for alternative fat production

Of the four verticals, precision fermentation emerged as a promising technology due to the efficiency of oil producing microbes and the ability to engineer metabolic pathways to adjust fatty acid profiles. However, the technoeconomics are currently challenging for fermentation processes that rely on conventional corn glucose. Multiple companies are exploring C1 feedstocks and sugar-rich waste streams as alternative feedstocks. As supply chains and technologies for these feedstocks (e.g. reducing variability in wastestreams and hydrogen electrolyzer scale-up) and strain performance improve, we see considerable potential in this sector in the future.

Therefore, despite the potential of some biological technologies, we concluded that none were compelling venture investment opportunities for our current fund, as it would be highly challenging from a technoeconomic perspective to address and resolve the limitations outlined above within our investment time horizon. However, just as with the production of recombinant protein ingredients, cultivated meat, and other technologies required to reshape our food system, there will not be one single solution for the vast array of use cases for fats in meat, dairy, and egg analogues. The speed of innovation in biology continues to accelerate and we’re looking forward to seeing breakthroughs in alternative fat R&D in companies and academia over the coming years.

A novel chemical approach to producing alternative fats

This conclusion meant we started to look beyond our four verticals to other solutions for the alternative protein industry’s fat challenge.

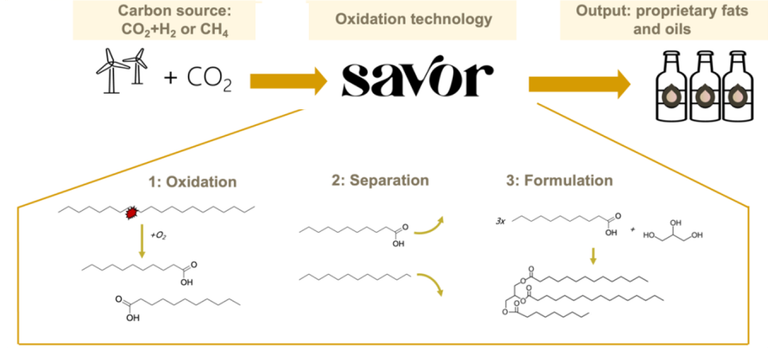

We first met the Savor team in early 2022. The company had just spun out of Orca Sciences, a climate-focused incubator and R&D organisation funded by Bill Gates. The founding team were in the early stages of developing a chemical process to produce cost-competitive functional alternative fats, with the overarching goal of decoupling food production from agriculture to create a more sustainable and economical food production system. Their thesis is summarised well in this blog post by Kathleen Alexander, Savor’s Co-founder and CTO. In simple terms, Savor takes carbon from a variety of sources, and then utilises several chemical processes, driven by specific catalysts, to produce synthetic fats that mimic animal fats. This is illustrated in Figure 3 below.

Figure 3: Savor’s chemical fat production process

Despite sitting outside of our existing 4 technology verticals, a chemical approach to producing fats made a lot of sense to us, given the structural simplicity of fat molecules, as compared to proteins. So, we took a deeper look…

Our analysis revealed that Savor’s chemical fat production system was compelling for five key reasons, as summarised below, and ultimately culminated in a lead investment in Savor’s Series A equity financing round in October 2023.

1) Superior unit economics: Savor’s fat production platform consists of a series of chemical processes. The technoeconomics of this process are compelling, and as a result, Savor has significantly lower production costs versus other alternative fat products, which rely on biological production systems, with the potential to achieve cost parity with commodity oils in the longer term.

2) Reduced scale up risk: Savor utilises existing chemical processes that already run at commercial scale in other (food and non-food) sectors. The engineering work required to scale is therefore not particularly complex, resulting in reduced scale up risk versus more novel technologies. This also means that Savor’s pathway to scale should be more accelerated, and as such, production volumes and revenues should be able to grow more quickly than competitors.

3) Demonstrated functional and sensory characteristics of early prototypes: Proof of concept of Savor’s chemical fat production platform has already been illustrated through early butter prototypes (butter has a high fat inclusion rate, and so is a good product to showcase Savor's alternative fat). These prototypes stand out from a taste and functionality perspective, and have been iterated to achieve an improved melting and crystallisation behaviour, hardness, viscosity, flavour, and other important properties.

4) Tunability and versatility: Savor’s synthetic fats are highly tunable. The ease of tuning Savor’s fat will allow the company to develop formulations that work well with different types of alternative protein, including alternative meat and alternative dairy. Savor’s fat is therefore likely to be more widely applicable to a range of potential end products versus many other alternative fat products.

5) Sustainability: Savor is producing an ingredient using a process that is entirely decoupled from agriculture. This is high impact from an emissions, land use, biodiversity and water perspective, as quantified in this article published recently in Nature Sustainability.

The food system of the future

We see a future where every ingredient is produced through the most efficient technological process. In the case of proteins, this is likely to be biological production systems, and in the case of fats, we have strong conviction that the most viable solution in the next 5-10 years is synthetic chemistry. We are excited by the prospect of the integration of novel biological and chemical systems to create a delicious, cost-effective, scalable, sustainable, and nutritious food system of the future.

[1] Jump, D. (2004). Fatty Acid Regulation of Gene Transcription. Critical Reviews in Clinical Laboratory Sciences, 41, 41 - 78. https://doi.org/10.1080/104083....

[2] Saini, R., & Keum, Y. (2018). Omega-3 and omega-6 polyunsaturated fatty acids: Dietary sources, metabolism, and significance - A review.. Life sciences, 203, 255-267 . https://doi.org/10.1016/j.lfs.....

[3] FAO. The Scientific Basis for Diet, Nutrition and Health Relationships. https://www.fao.org/3/x0243e/x...

[4] Dransfield, E. (2008). The taste of fat. Meat Science, 80(1), 37–42. https://doi.org/10.1016/j.meat...

[5] Day, Edgar a. “Role of milk lipids in flavors of dairy products.” In flavor chemistry, 56:94–120. Advances in chemistry 56. American chemical society, 1969. Https://doi.org/10.1021/ba-196....