The isolation of proteins from plant sources is a critical process in biochemistry and food science, playing a vital role in various applications ranging from nutritional supplements to pharmaceuticals. This intricate procedure involves extracting proteins while preserving their structural integrity and functionality, often utilizing methods such as solvent extraction, precipitation, and chromatographic techniques. Given the diverse array of plant species, each with unique protein profiles, efficient isolation techniques can enhance the recovery of specific proteins with desirable properties, paving the way for innovations in health, nutrition, and biotechnology. As the demand for plant-based proteins continues to rise, understanding the methods and principles behind their isolation becomes increasingly important for researchers and industry professionals alike.

Enhancing Protein Yield in Plant Extraction: Effective Methods and Techniques

To enhance protein yield during extraction from various plant sources, several methods can be employed, including optimizing the extraction solvent and its pH to improve solubility, utilizing enzymatic treatments (such as proteases) to break down cell walls and release proteins more effectively, increasing temperature and agitation during the extraction process to facilitate protein solubilization, and applying novel techniques like ultrasound or microwave-assisted extraction to disrupt plant matrices. Additionally, employing sequential extraction processes, where different solvents are used at various stages, can help in maximizing protein recovery while minimizing denaturation, and using membrane filtration methods can concentrate proteins post-extraction, further enhancing overall yield.

Impact of Solvent Choice on the Purity and Functionality of Isolated Plant Proteins

The choice of solvent significantly influences the purity and functionality of isolated plant proteins by affecting their solubility, stability, and extraction efficiency. Different solvents can selectively dissolve various proteins based on their polarities and hydrophobic properties, which impacts the degree of protein aggregation and denaturation during extraction. A suitable solvent can enhance the extraction of desired proteins while minimizing the co-extraction of unwanted compounds such as lipids, carbohydrates, and phenolic compounds, thus improving overall purity. Moreover, the solvent's pH and ionic strength can alter protein structure and functional properties, including emulsification, foaming, and gelation capabilities, ultimately determining the efficacy of the isolated proteins in food or industrial applications.

Impact of Temperature and pH on the Solubility and Stability of Plant Proteins During Isolation

Temperature and pH are critical factors influencing the solubility and stability of plant proteins during isolation. Elevated temperatures can enhance protein solubility by disrupting hydrophobic interactions, but excessive heat may denature proteins, leading to loss of functionality. Meanwhile, pH affects the ionization of amino acid side chains, which influences the protein's charge and solubility; at a protein's isoelectric point, solubility decreases due to reduced electrostatic repulsion among molecules, causing aggregation. Thus, optimizing temperature and pH during protein isolation processes is essential for maximizing yield and maintaining the functional integrity of the proteins.

Influence of Anti-Nutritional Factors on Protein Extraction Efficiency from Plant Materials

The presence of anti-nutritional factors in plant materials can significantly influence protein extraction efficiency by interfering with the solubility and bioavailability of proteins. Compounds such as lectins, tannins, and protease inhibitors can bind to proteins or form complexes that decrease their solubility in extraction solvents, making it more difficult to isolate them from the plant matrix. Additionally, these anti-nutritional factors may precipitate proteins or promote aggregation, further reducing the yield of extracted protein. Understanding and mitigating the effects of these factors through processing methods, such as heat treatment or enzymatic hydrolysis, can improve protein extraction outcomes and enhance the nutritional quality of plant-based protein sources.

Potential Effects of Different Drying Techniques on the Quality of Isolated Proteins from Plants

Different drying techniques can significantly impact the quality of isolated proteins from plants by influencing their structural integrity, functional properties, and nutritional value. Methods such as freeze-drying preserve the proteins' native structures and functionalities, leading to higher solubility and better emulsifying properties, while air-drying or spray-drying may result in denaturation and loss of bioactive components due to exposure to heat and oxygen. Additionally, the rate of moisture removal and the presence of reactive compounds during drying can affect the protein's amino acid composition and overall digestibility. Consequently, the choice of drying technique is crucial for maintaining the desired quality attributes of plant-based proteins for food applications.

Enhancing Plant Protein Extraction and Recovery through Enzymatic Treatments

Enzymatic treatments can enhance the extraction and recovery of plant proteins by breaking down cell walls, thereby facilitating the release of proteins into the surrounding solution. Enzymes such as cellulases, pectinases, and proteases target specific polysaccharides and proteins within plant tissues, improving solubilization and reducing viscosity. This leads to higher yields and purity of extracted proteins while minimizing the need for harsh chemicals or extreme conditions that can denature the proteins. Additionally, enzymatic processes can enhance the digestibility and bioavailability of the proteins, making them more beneficial for nutritional applications. Overall, these treatments contribute to more efficient and sustainable protein extraction methods in food and feed production.

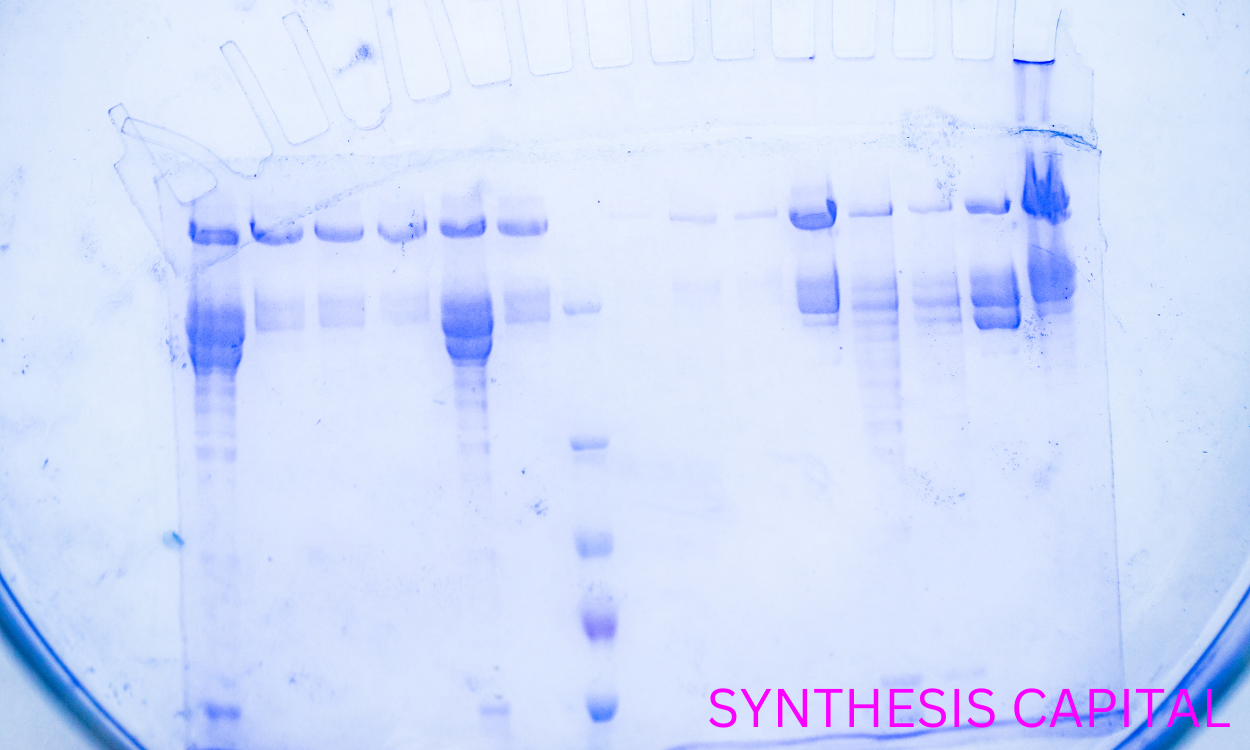

Impact of Purification Techniques on the Biological Activity of Isolated Plant Proteins: A Focus on Dialysis and Chromatography

Purification techniques like dialysis and chromatography can significantly impact the biological activity of isolated plant proteins by altering their structural integrity, folding, and functional properties. Dialysis, which removes small molecules and impurities, may help maintain protein stability but can also lead to the loss of essential cofactors or ligands that are crucial for the protein's activity. Chromatography, on the other hand, separates proteins based on various properties such as size, charge, or affinity, which can enhance purity but might also cause denaturation or conformational changes if conditions (such as pH or temperature) are not meticulously controlled. Consequently, the choice of purification technique and its parameters play a critical role in preserving the functional characteristics of plant proteins, influencing their potential applications in biotechnology, food science, and pharmacology.

Challenges Associated with Scaling Up the Protein Isolation Process for Industrial Applications

Scaling up the protein isolation process for industrial applications involves several challenges, including maintaining product purity and activity while increasing yield and efficiency. The transition from laboratory to industrial scale can lead to issues such as changes in physical properties of the proteins, variations in solubility and stability, and difficulties in controlling environmental conditions like temperature and pH. Additionally, ensuring reproducibility and consistency across larger batches can be complicated by equipment limitations and the need for optimization of downstream processing steps to separate and purify proteins effectively. Economic factors, such as the cost of raw materials, processing, and regulatory compliance, also play a crucial role in determining the feasibility of scaling these processes.