Proteases are enzymes that play a crucial role in breaking down proteins into amino acids, making them essential for various biological processes. One common source of protease enzymes is bacteria, which naturally produce these enzymes as part of their metabolic activities. Extracting protease enzymes from bacteria involves a series of steps to isolate and purify the enzyme for use in various industrial applications such as food processing, detergent manufacturing, and pharmaceuticals. This process typically involves cell disruption, extraction of the enzyme, purification through chromatography techniques, and characterization of the enzyme's properties. By harnessing the protease enzymes produced by bacteria, researchers and industries can benefit from their unique catalytic abilities and specificity in protein degradation.

Methods for Extracting Protease Enzyme from Bacteria

Common methods for extracting protease enzyme from bacteria include cell disruption techniques such as sonication, homogenization, or freeze-thaw cycles to break open the bacterial cells and release the enzyme. Once the cells are disrupted, the enzyme can be purified using techniques like centrifugation, filtration, chromatography, or precipitation. These methods help to isolate and concentrate the protease enzyme from other cellular components, allowing for further analysis and potential industrial applications.

How does the efficiency of extraction vary depending on the type of bacteria being used?

The efficiency of extraction can vary depending on the type of bacteria being used due to differences in cell wall composition, enzyme production, and metabolic pathways. Some bacteria have thick cell walls that are difficult to disrupt, leading to lower extraction efficiency, while others may produce enzymes that aid in breaking down cell membranes and releasing desired compounds. Additionally, certain bacteria may have specific metabolic pathways that make them more efficient at producing target compounds, resulting in higher extraction yields. Overall, understanding the characteristics of the bacteria being used is crucial in optimizing extraction efficiency for different applications.

Are there any challenges or limitations in extracting protease enzyme from bacteria?

There are several challenges and limitations in extracting protease enzyme from bacteria, including the variability in enzyme production among different bacterial strains, the need for specific growth conditions to optimize enzyme yield, the potential for contamination of the enzyme extract with other unwanted proteins or compounds, and the cost and time associated with scaling up production for commercial use. Additionally, some bacterial proteases may be unstable or require specific cofactors for activity, further complicating the extraction process. Overall, careful optimization and purification techniques are necessary to overcome these challenges and ensure the successful extraction of protease enzymes from bacteria.

Verifying the Purity of Extracted Protease Enzyme

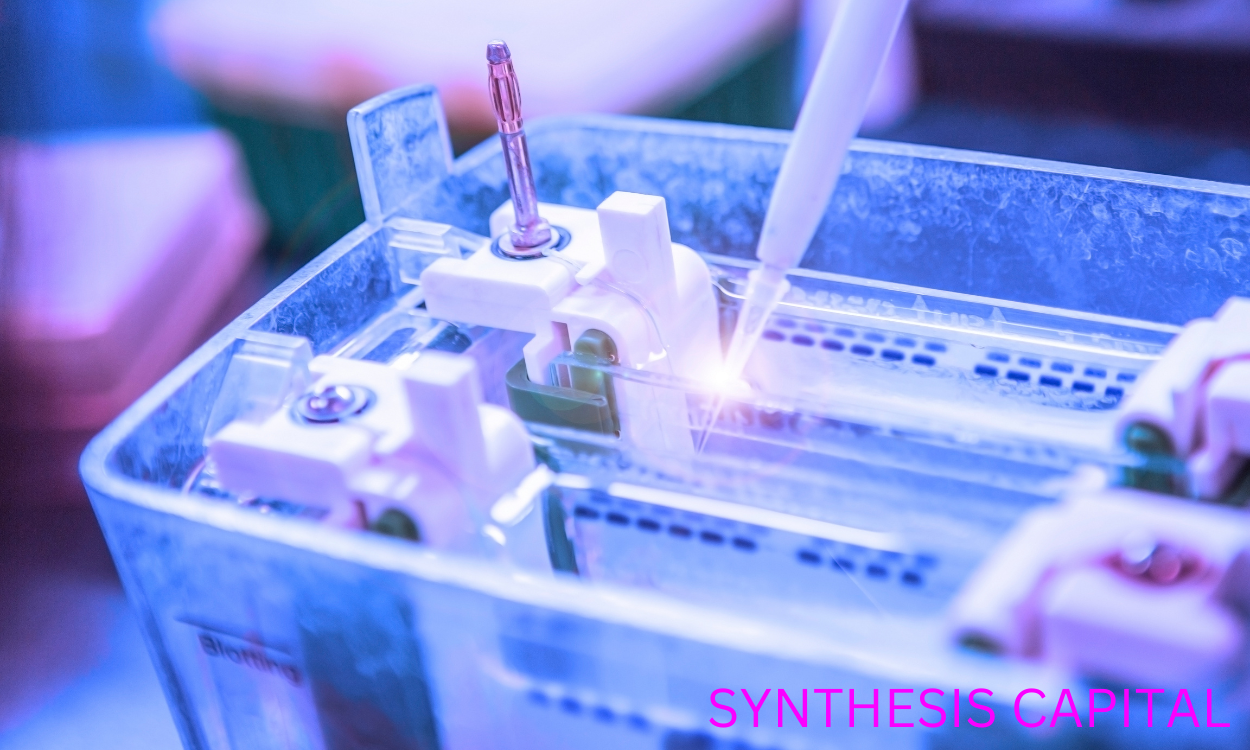

The purity of the extracted protease enzyme is verified through various methods such as SDS-PAGE (sodium dodecyl sulfate polyacrylamide gel electrophoresis) which separates proteins based on their molecular weight, allowing for visualization of the enzyme band. Additionally, enzyme activity assays can be conducted to confirm the presence of protease activity in the sample. Furthermore, mass spectrometry analysis can be utilized to identify and quantify the different protein components present in the extract, ensuring that the enzyme of interest is pure and free from contaminants. Overall, a combination of these techniques helps in verifying the purity of the extracted protease enzyme.

Factors Affecting the Yield of Protease Enzyme Extraction from Bacteria

The yield of protease enzyme during extraction from bacteria can be influenced by various factors such as the type of bacteria used, the growth conditions of the bacteria, the method of cell disruption, the pH and temperature of the extraction process, the presence of inhibitors or activators, and the efficiency of the purification steps. Different bacterial strains may produce varying levels of protease enzymes, while optimal growth conditions such as nutrient availability, oxygen levels, and incubation time can impact enzyme production. The method of cell disruption, whether mechanical or chemical, can affect the release of protease enzymes from within the bacterial cells. Additionally, the pH and temperature during extraction can influence enzyme stability and activity, and the presence of inhibitors or activators in the extraction process can either enhance or inhibit enzyme activity. The efficiency of purification steps such as filtration, chromatography, or precipitation can also impact the final yield of protease enzyme extracted from bacteria.

Are there any novel techniques or technologies being developed for more efficient extraction of protease enzyme from bacteria?

Researchers are currently exploring novel techniques and technologies such as ultrasound-assisted extraction, enzyme immobilization, and genetic engineering to improve the efficiency of protease enzyme extraction from bacteria. These methods aim to increase the yield of protease enzymes while reducing processing time and costs. Ultrasound-assisted extraction utilizes high-frequency sound waves to disrupt bacterial cell walls and release protease enzymes more efficiently. Enzyme immobilization involves attaching protease enzymes to a solid support, allowing for easier separation and reuse of the enzymes. Genetic engineering techniques can be used to enhance the production of protease enzymes within bacteria, resulting in higher yields of the desired enzyme. Overall, these advancements in extraction techniques hold promise for increasing the efficiency and sustainability of protease enzyme production from bacteria.

How do researchers determine the optimal conditions for extracting protease enzyme from bacteria?

Researchers determine the optimal conditions for extracting protease enzyme from bacteria through a series of experiments that involve varying factors such as pH, temperature, incubation time, and concentration of bacterial cells. By systematically testing different combinations of these variables and measuring extraction of protease enzyme from bacteria the resulting enzyme activity levels, researchers can identify the conditions that yield the highest enzyme production. This process allows them to optimize the extraction process and maximize the efficiency of protease enzyme production from bacteria for various industrial and research applications.

What potential applications or industries could benefit from the successful extraction of protease enzyme from bacteria?

The successful extraction of protease enzyme from bacteria could benefit a wide range of industries and applications. In the pharmaceutical industry, protease enzymes are used in drug development and production processes, such as the synthesis of antibiotics and cancer treatments. In the food industry, protease enzymes play a crucial role in food processing, including cheese making, meat tenderizing, and brewing. Additionally, protease enzymes have potential applications in the textile industry for fabric softening and in the leather industry for tanning processes. Overall, the successful extraction of protease enzyme from bacteria has the potential to revolutionize various industries by enhancing efficiency, quality, and sustainability in their processes.

The Efficient Extraction of Protease Enzyme from Bacteria

1. Use a suitable bacterial strain that produces high levels of protease enzyme.

2. Optimize growth conditions such as temperature, pH, and nutrient availability to maximize enzyme production.

3. Harvest the bacterial cells at the optimal stage of growth to ensure maximum enzyme yield.

4. Disrupt the bacterial cells using techniques like sonication or bead beating to release the intracellular protease enzyme.